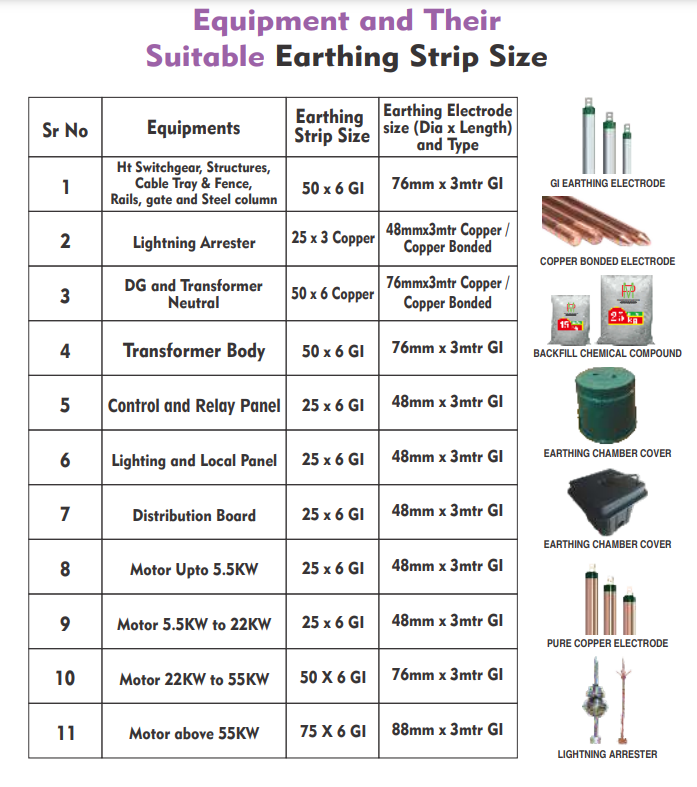

Earthing Stripes

Earthing strips are employed to divert the fault current through an alternative route to the ground so as to safeguard the equipment.

What to look while selecting earthing strip?

The earthing strip should exhibit low resistance to electrical current, should be able to withstand the impact of corrosion inducing agents and must be capable of dissipating abnormal fault current regularly.

The strips should be constructed out of superior quality copper, aluminium or Galvanized Iron (GI). Flexibility in thickness and width should be present.

A normal earthing strip have its thickness between 3 to 6 mm whereas the width vary from 15 -100 mm. This flexibility ensures that the strip can prove useful in varied applications.

The thermal and electrical conductivity of the earthing strip should be good. Galvanized strips come loaded with all the qualities that you may seek in a perfect earthing strip. Disregard of safety matters and use of faulty electrical equipment have claimed many lives. Hence the earthing strip you choose for your application should have accurate dimension, robust build and corrosion resistance. Galvanized earthing strips are manufactured using premium quality iron or steel.

The strips are subject to galvanization in accordance with the ISI specifications. Earthing strips are most preferred in areas where the soil conditions are rocky. The coating of zinc on the galvanized strips is recommended to be a minimum of 80 microns. The hot dipped galvanized iron strips have a width in the range of 25-75 mm and thickness of 3-12 mm.

The strips have protracted life and require very little maintenance during their lifetime.